-

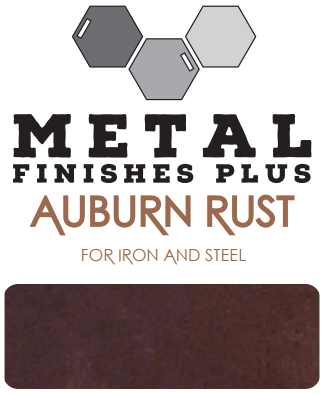

Auburn Rust Oxidizer

$9.90 – $49.90Auburn Rust instantly begins the rusting process on most types of steel. A multitude of decorative rust effects can be produced in a relatively short time span, ranging from several minutes to a few hours. The actual difference between the Rust Oxidizers is pretty subtle.Contact time, humidity, alloy tempetature etc. determine the final color and texture. This unique formula combines a foundation of copper with the look of rusted steel. With these safe, easy to use formulas, scores of ornamental rust finishes can be created. Simply alter the humidity, temperature or rusting time and alter the final finish. With Auburn Rust, ornamentally rusting ferrous metals has never been so fast, easy, and safe. -

Acrylic Sealer

$29.90 – $89.90Metal Finishes PLUS' clear acrylic sealers' are tough, semi-gloss or matte sealer design to prevent oxygen and moisture from coming into contact with the surface of finished parts. The use of either of our acrylic sealers' helps to protect, maintain and preserve the looks and colors produced with our other finishes. This sealer sprays on smooth and dries quickly to facilitate application of multiple, thin coats. Formulated with 23% solids, our acrylic sealers' contains UV protection and are suitable for use indoors or outdoors. Our sealers may be applied on metal, wood, ceramic, tile, nearly any surface. -

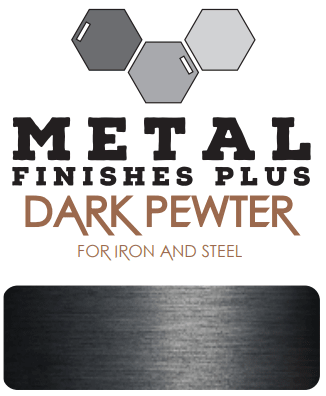

Dark Pewter Steel Finish

$17.90 – $59.90Dark Pewter will darken steel, steel alloys, "pot" metal, brass and many other metals to various shades of pewter gray. Dark Pewter is primarily used to give metal parts an aged, antique appearance. This product may be used as a spray, but the best method of application is immersion. The longer a part is left in the solution, the darker it will become. Most users opt to quick dry the darkened parts and then burnish them before sealing. This process will brighten the high spots and leave the recesses darkened. The result is a natural looking aged, pewter-like finish. If the darkened part is allowed to air dry and oxidize, differing shades of green rust will form. This can produce interesting and attractive finishes, so experimentation is worthwhile. Dark Pewter will also darken parts plated with our Copper Plate solution. Different effects are produced on different types of metal as not all metals will react in the same fashion. -

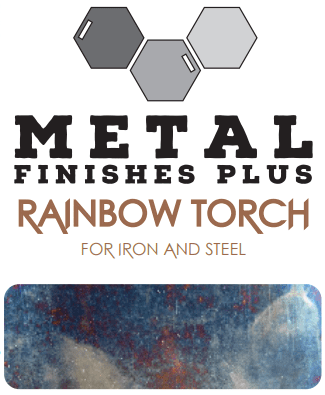

Rainbow Torch Steel Finish

$14.90 – $54.90This solution is designed to be used on steel in conjunction with our Copper Plate. Rainbow Torch will create a wide variety of colors similar to those produced by the application of intense torch heat upon steel. These effects are easy to create, and are limited only by your imagination. With a little practice, a competent metal finisher can render extremely complicated colorful patterns and designs on steel in this easy to use, two step process. Many shades of blue, gray, green, red, and brown result when this solution is sprayed on top of our Copper Plate solution. The end result is a bright, colorful, multi-hued finish. If you desire a more subtle look, these colors and textures may be further altered by allowing the finished part to oxidize naturally for a controlled period of time. Oxidation softens and textures the colors, resulting in a more matte-like finish. -

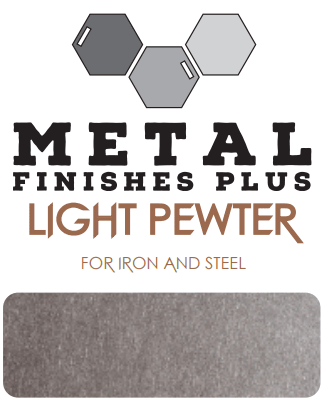

Light Pewter Steel Finish

$17.90 – $59.90Light Pewter will darken steel, steel alloys, "pot" metal, brass and many other metals to various shades of pewter gray. Light Pewter is primarily used to give metal parts an aged, antique appearance. This product may be used as a spray, but the best method of application is immersion. The longer a part is left in the solution, the darker it will become. Most users opt to quick dry the darkened parts and then burnish them before sealing. This process will brighten the high spots and leave the recesses darkened. The result is a natural looking aged, pewter-like finish. If the darkened part is allowed to air dry and oxidize, differing shades of green rust will form. This can produce interesting and attractive finishes, so experimentation is worthwhile. Light Pewter will also darken parts plated with our Copper Plate solution. Different effects are produced on different types of metal as not all metals will react in the same fashion. -

Gun Metal Blue Steel Finish

$18.90 – $67.90This formula works on steel and steel alloys to form various shades of colors ranging from blue to black. The finish is similar in appearance to the results of a traditional hot bluing process, but is done at room temperature. Beautiful blue/black finishes can be created by anyone, safely at room temperature. Simply spray or immerse parts in the Gun Metal Blue solution and watch the finish begin to darken. The process can be stopped at any time by removing the part and rinsing with water. This allows the user to create many different colors along the blue-black range in a matter of seconds. -

Midnight Black Steel Finish

$18.90 – $67.90Our Midnight Black solution darkens steel and non-stainless steel alloys at room temperature without the need for any special equipment. This unique formula can be applied by immersion, spray or by brush for detailed areas. The color of the blackened surface may be burnished to lighten the intense darkness before sealing. After plating and/or coloring, finished parts may be quick dried and sealed, or allowed to oxidize. Oxidation will alter the colors and textures, creating an additional palate of finish effects. -

Antique Red / Brown Steel Finish

$18.90 – $67.90Our Antique Red/Brown solution plates steel and non-stainless steel alloys at room temperature without the need for any special equipment. This unique formula can be applied by immersion, spray or by brush for detailed areas. This darkening solution produces a Reddish/Brown finish. The color of the plated surface may be burnished to lighten the finish before sealing. After plating and/or coloring, finished parts may be quick dried and sealed, or allowed to oxidize. Oxidation will alter the colors and textures, creating an additional palate of finish effects. -

Rust Arrest

$9.90 – $49.90Rust Arrest is a neutralizing agent designed to stop the chemical reactions that take place when applying any of our steel finishes or patina solutions onto metal. Rust Arrest aids in preventing white salt leaching, pealing, rust bleed through, and other problems that may periodically occur when using our steel finishing products. Rust Arrest is a quick and easy to use tool for your metal finishing tool box. -

Gold Rust Oxidizer

$9.90 – $49.90Gold Rust instantly begins the rusting process on most types of steel. A multitude of ornamental rust effects can be produced in a relatively short time span, ranging from several minutes to a few hours. The actual difference between the Rust Oxidizers is pretty subtle. Contact time, humidity, alloy temperature etc. determine the final color and texture. This unique formula combines a foundation of copper with the look of rusted steel. With these safe, easy to use formulas, scores of ornamental rust finishes can be created. Simply alter the humidity, temperature or rusting time and alter the final finish. -

Copper Rust Oxidizer

$9.90 – $49.90Copper Rust instantly begins the rusting process on most types of steel. A multitude of ornamental rust effects can be produced in a relatively short time span, ranging from several minutes to a few hours. The actual difference between the Rust Oxidizers is pretty subtle. Contact time, humidity, alloy temperature etc. determine the final color and texture. This unique formula combines a foundation of copper with the look of rusted steel. With these safe, easy to use formulas, scores of ornamental rust finishes can be created. Simply alter the humidity, temperature or rusting time and alter the final finish. With Copper Rust, ornamentally rusting ferrous metals has never been so fast, easy, and safe. -

Patina Oxidizer

$9.90 – $49.90Patina is designed for use on copper, brass, bronze, and our metal alloy metallic coatings. Patina reactions produce all of the various shades of blue & blue/greens that are so familiar with aged copper, brass, and bronze. This solution can be applied directly onto metal alloys, or onto the final, tacky coat of one of our metallic coatings. On metal alloys, Patina will react to form shades of purple, blue, and turquoise blue/green. When applied to one of our metallic coatings, the colors are determined by the coating being used, though they tend toward a variety of blues and greens. Regardless of the medium being used, colors may be altered with water mists or by subjecting the parts to high humidity for various periods of time.